Jaggery plant with specifications “30 TCD” refers to a jaggery (also known as “gur” or “panela”) production plant with a capacity of processing 30 tons of sugarcane per day. The “TCD” stands for “Tons of Cane per Day,” which indicates the processing capacity of sugarcane. In this case, the plant can process 30 tons of sugarcane daily.

The plant has a processing capacity of 25 tons of sugarcane per day, meaning it can produce 25 tons of jaggery daily. The plant operates on a voltage of 440 volts, which is a common industrial voltage level. The frequency of the power supply is 60 Hz, which is the standard frequency used in many countries. The plant’s power consumption can go up to 10 kilowatts (kW), indicating the maximum electrical power it may require during operation. The main construction materials for the plant’s structure are Mild Steel (MS) and Stainless Steel (SS), which are commonly used for industrial machinery and equipment due to their durability and resistance to corrosion.

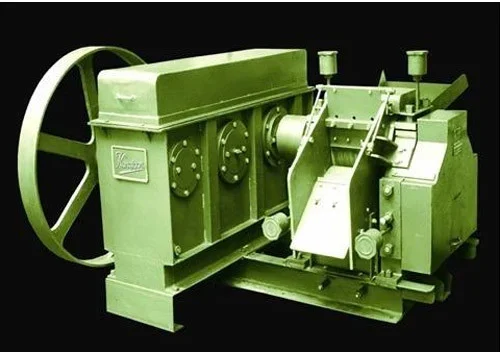

Electric Jaggery Making Machine automates jaggery production from sugarcane juice, replacing manual labour and open pans for a hygienic and efficient process. It uses rollers or a crusher to extract juice, removing the need for manual crushing and then filters the juice to remove impurities. The boiling unit, equipped with electric heaters, heats the juice, leading to water evaporation and jaggery formation with impurities skimmed off for a clean end product. Controlled and powered by electricity, it offers convenience and reduces labour for moulding the jaggery into shapes or cooling and collecting the final product. These machines are popular in small to medium-scale jaggery production units, providing a cost-effective and time-efficient solution while preserving cultural and culinary significance.

The body material of the machine is CS, which stands for Carbon Steel. Carbon steel is a strong and durable material commonly used in industrial equipment. The machine operates at a frequency of 50/60 Hz, which means it can be used in areas with either a 50 Hz or 60 Hz power supply. The machine operates on a three-phase electrical system, which is common for industrial-grade machines. The machine’s weight is up to 600 kg, indicating the maximum weight of the equipment, which may vary based on its specific configuration and capacity.

Jaggery Making Machine streamlines and automates jaggery production from sugarcane juice, replacing manual methods with a more efficient approach. It includes a sugarcane crusher for juice extraction, eliminating the need for manual crushing and improving productivity. The extracted juice undergoes filtration to remove impurities, ensuring a cleaner end product. Equipped with electric heaters, the boiling unit heats the juice to form jaggery, with impurities removed during the process. Modern machines may feature automation, temperature control, and stainless steel construction, enhancing efficiency and durability for widespread use in jaggery production units.

The machine has a high processing capacity of more than 100 tons of sugarcane per day, resulting in a significant jaggery production output. The body material of the machine is MS, which stands for Mild Steel. Mild steel is a commonly used material for industrial machinery due to its strength and durability. The machine operates on a voltage of 380 volts, which is a standard industrial voltage level. The machine’s power supply operates at a frequency of 60 Hz, which is commonly used in many countries. The machine’s weight is up to 500 kg, indicating its relatively lightweight design and easy manoeuvrability

WhatsApp us